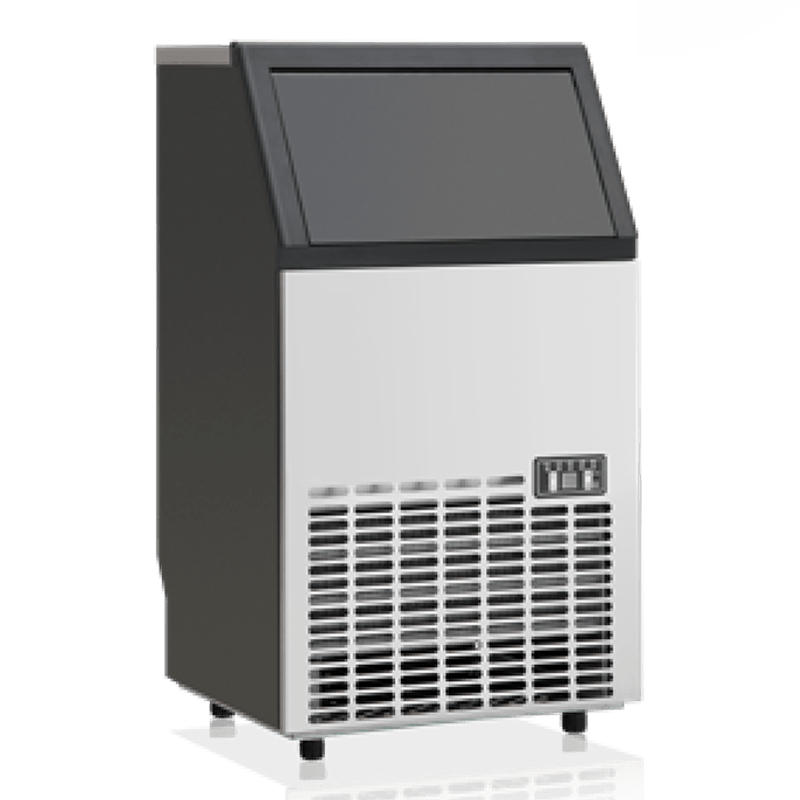

How Deep Refrigeration Technology Enhances Ice Production in Modern Commercial Ice Maker Machines

Deep refrigeration has become a game-changer in the world of commercial ice maker machines. At first glance, the concept may seem straightforward—lower temperatures mean faster freezing—but the underlying mechanics are far more nuanced. Deep refrigeration doesn’t just freeze water quickly; it controls crystallization, reduces energy waste, and improves the clarity and density of the ice produced. For businesses that rely on consistent ice output—like restaurants, seafood processors, or cold chain logistics—these technical improvements translate directly into operational reliability and quality assurance.

The key advantage of deep refrigeration is its ability to maintain ultra-low and stable internal temperatures. Unlike standard cooling systems that operate on broader temperature cycles, commercial ice machines equipped with deep refrigeration can push the internal environment well below freezing with minimal fluctuations. This stability leads to finer ice crystal formation, which results in clearer, harder ice cubes with fewer air bubbles. In applications where ice purity and durability matter—such as in high-end cocktail bars or pharmaceutical storage—these differences are more than aesthetic; they impact performance.

In engineering terms, achieving deep refrigeration requires precise compressor performance and optimal insulation. That’s why many advanced commercial ice maker machines today integrate high-efficiency compressors such as those using R134a or R290 refrigerants. These systems can pull down temperatures rapidly without overburdening energy consumption, and they tend to operate more quietly and reliably. Combined with thickened insulation foam and high-density door seals, these machines retain cold more effectively, reducing the compressor’s workload and lowering operating costs.

But deep refrigeration isn't only about performance—it’s also about consistency. A commercial ice maker machines operating in a hot kitchen or under frequent access conditions needs to recover temperature quickly to maintain ice quality. Deep refrigeration provides that resilience. Even during peak hours, the ice-making process remains stable, minimizing variations in cube size or texture. This ensures that the output matches customer expectations, even under demanding usage. From a professional kitchen standpoint, consistency is king—and a deep refrigeration system helps deliver it every time.

One often overlooked benefit is its role in machine longevity. When the internal system doesn't have to cycle as frequently between high and low temperatures, component wear is reduced. This leads to fewer service calls, longer intervals between maintenance, and more predictable operation—something every commercial kitchen manager can appreciate. Especially for businesses looking to invest in a durable and efficient commercial ice maker, understanding the value of deep refrigeration can be a key decision-making factor.

At our manufacturing facility, we've seen how pairing deep refrigeration with intelligent controls and stainless steel construction leads to superior results across industries. Whether you're storing bulk ice for seafood display or producing crystal-clear cubes for upscale service, the combination of technology and design matters. It's not just about making ice; it's about doing it better, faster, and more dependably. And with customization options in temperature, size, and layout, there's never been a more flexible time to upgrade your ice-making capability.

For any business searching for a long-term solution that balances performance with energy efficiency, a commercial ice maker machine equipped with deep refrigeration is an investment that pays off daily. It’s this attention to engineering detail and industry feedback that drives us to continually improve what we offer. After all, great ice starts with a great machine—and that’s something we’re proud to deliver.

English

English русский

русский Español

Español عربى

عربى