Commercial refrigeration secrets for better display cabinets

Image Source: pexels

Commercial refrigeration is very important for keeping food, ice cream, and desserts fresh in . A study in a supermarket showed that opening doors often makes the unit use more energy and take longer to cool down, by more than 5%. ENERGY STAR certified equipment uses about 40% less energy than regular models. This can save you hundreds of dollars each year. Operators who watch temperature, airflow, and lighting can make products look better and spend less money.

Key Takeaways

-

Keep the right temperature in display cabinets. This keeps food safe and fresh. Use wire shelves to help air move. This keeps the temperature steady.

-

Check and clean vents, filters, and door seals often. This helps air flow well and saves energy.

-

Use LED lighting to make products look nicer. It also saves energy. Arrange products neatly. This helps light and air move better.

-

Pick ENERGY STAR certified units. Use night blinds or energy-saving modes. This lowers energy bills and helps the environment.

-

Clean display cabinets every day. Call a professional for problems like ice buildup or strange noises. This keeps equipment working well.

Temperature Control

Keeping the right temperature in commercial refrigeration units is very important. It helps keep food safe and keeps products looking good. Different refrigeration equipment needs different temperature settings. For example, reach-in freezers and glass door display cabinets need their own settings. Research shows many refrigerators do not stay at 5°C (41°F) or lower. This can make food unsafe. The type of refrigerator, shelf material, and how full it is can change the temperature inside. Wire shelves let air move better than solid glass shelves. This helps keep the temperature even in the cabinet.

Tip: Try to use wire shelves in display cabinets. This lets air move around and keeps the temperature steady.

Ideal Settings

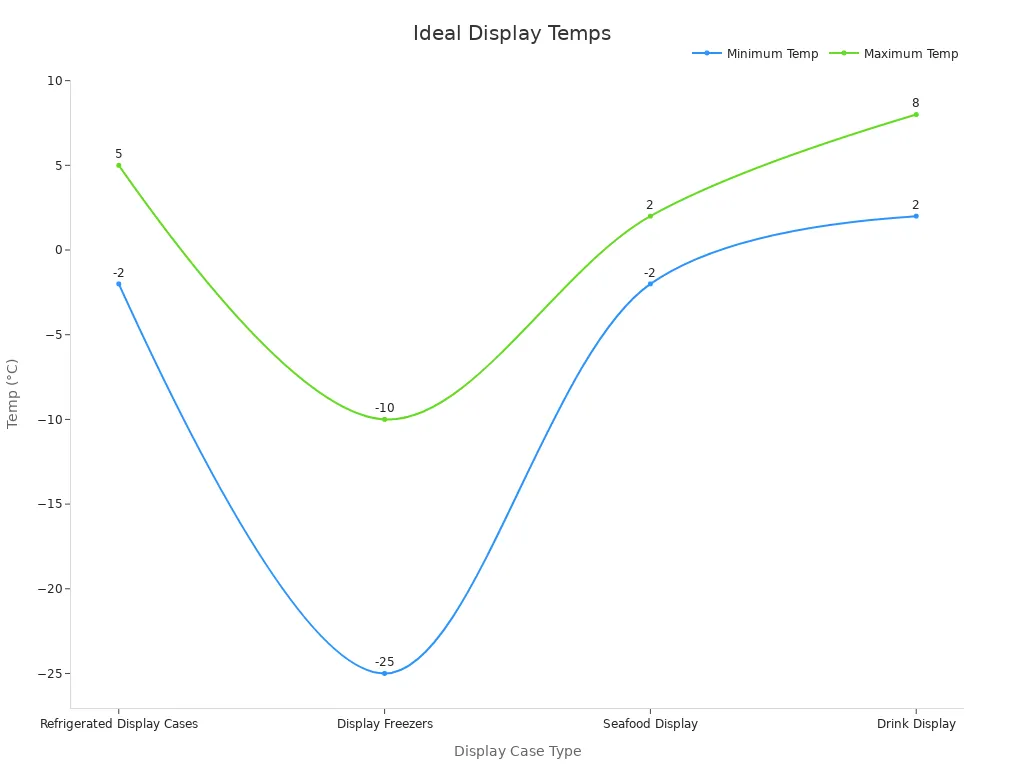

Operators should set each unit to the best temperature for its job. The tables below show the best temperature ranges for different freezers and display cases. These numbers come from industry standards and food safety rules:

|

Equipment Type |

Ideal Temperature Range |

Purpose/Notes |

|---|---|---|

|

Reach-in Freezers |

Stops bacteria and keeps food good |

|

|

Glass Door Display Cabinets |

Keeps food safe and fresh; depends on food |

|

Display Case Type |

Temperature Range |

Purpose/Notes |

|---|---|---|

|

Refrigerated Display Cases |

Keeps food safe, depends on food |

|

|

Display Freezers |

-10°C to -25°C (14°F to -13°F) |

Keeps food safe and follows health rules |

Seafood displays should be between -2°C and 2°C. Drink displays can be set between 2°C and 8°C. Cold holding temperatures should always be 5°C (41°F) or lower. This stops harmful bacteria from growing.

Our website’s display cabinets use advanced cooling technology. This keeps the right temperature. Food, ice cream, and desserts stay fresh and look good for customers.

Monitoring & Calibration

Good temperature control needs regular checks and calibration. Modern systems use wireless sensors to watch temperature and humidity all the time. These sensors send alerts if the temperature goes out of the safe range. Staff can act fast to stop food from spoiling. This also helps businesses follow food safety rules and keep records for audits.

Many people think the thermostat shows the real temperature inside. But this is not always true. Without good monitoring tools, it is easy to miss changes that can hurt food quality. Using electric temperature controls and checking sensors often can help a lot.

Regular calibration makes a big difference. In one study, calibration lowered the average error by 69% in refrigeration zones and 82% in freezer zones. This means calibration makes temperature readings more accurate and meets industry standards.

|

Metric |

1st Temperature Zone (Refrigeration) |

2nd Temperature Zone (Freezer) |

|---|---|---|

|

Mean Absolute Error (MAE) Before Calibration |

0.64 °C |

0.19 °C |

|

Mean Absolute Error (MAE) After Calibration |

0.41 °C |

0.007 °C |

|

Percentage Reduction in MAE |

69% |

82% |

Note: Calibrating often makes readings more accurate. It also helps your business follow food safety standards like EN12830.

By using these tips for temperature control, operators can keep products safe, waste less, and make displays look better. Commercial refrigeration units from our website have good temperature controls and easy-to-read displays. This makes it easy to keep food safe and looking nice.

Airflow & Circulation

Preventing Hot Spots

Good airflow in commercial refrigeration cabinets keeps the temperature even. This stops hot spots from forming. Hot spots make some food spoil faster. This means more waste and shorter shelf life. Food safety experts use HACCP principles to find and fix hazards. They look for temperature changes that can be risky. Experts say to cool food quickly and keep the temperature the same everywhere. This stops bacteria from growing in hot spots.

|

Factor/Aspect |

Description |

Impact on Hot Spot Prevention and Shelf Life |

|---|---|---|

|

HACCP Principles |

Finds and controls storage hazards |

Watches key points to stop bacteria from growing |

|

Cooling Method |

Cools food below 10°C in 2 hours |

Keeps temperature even and stops bacteria in hot spots |

|

Temperature Control |

Keeps food out of the 10°C to 60°C danger zone |

Helps keep food safe and last longer |

Low airflow is the main reason systems do not work well. It can freeze coils and break compressors. It also makes energy bills go up. Dirty filters or blocked vents make fans work harder. This uses more energy. Cleaning filters and changing fan speed can save energy. It also helps equipment last longer.

Tip: Staff should check vents and filters every week. Clean or change them when needed to keep airflow strong.

Our website’s display cabinets have special airflow systems. These systems help keep food, ice cream, and desserts fresh and safe for longer.

Product Organization

How staff put products in the cabinet changes how well it cools. If products block vents or are packed too tight, cold air cannot move. This causes uneven temperatures and hot spots. Studies in data center cooling show that better airflow paths help cooling. The Effective Cooling Ratio (ECR) shows how good organization makes cooling better.

-

Leave space between items so air can move.

-

Do not stack products against the back wall or over vents.

-

Rotate stock so older items stay in the coldest spots.

Good product organization keeps food safe. It also saves energy and helps equipment last longer.

Our display cabinets have shelves you can move and smart airflow design. These features help staff organize products for freshness and a nice look.

Lighting & Display

Lighting Choices

Lighting is very important for how products look in commercial refrigeration display cabinets. LED lighting is the best option for new units. LEDs are brighter and cleaner than old bulbs. They last a long time, sometimes up to ten years. This means you do not need to change them often. It also saves money on repairs. Operators can put LED strips around the case. This helps show off products from all sides. Food, ice cream, and desserts look better to customers.

LEDs come in many color temperatures. Staff can pick warmer or cooler lights. This makes packaging and food colors pop. Studies say LED lighting helps people see products better. It also makes shopping feel nicer. Customers notice bright displays and feel happy. This can make them buy more. LEDs work well in cold places and use less energy. This lowers lighting and cooling bills. Using energy-saving doors with LED lighting saves even more energy and makes displays look great.

Tip: Pick LED lighting for display cabinets. It saves energy and makes products look great.

Our website’s display cabinets use special LED systems. These systems keep food and desserts fresh and looking nice all the time.

Product Arrangement

How staff put products in the cabinet changes how easy they are to see and how much energy is used. Putting items in neat rows with space between them lets light reach every product. This stops shadows and helps customers see everything. Operators should not block lights or vents with big items. Good arrangement also lets cold air move well. This keeps all products at the right temperature.

Research using computer tools like TRNSYS and EnergyPlus found that smart window controls and good product placement can cut cooling energy by up to 29%. Good lighting patterns and smart product placement help people see better and use less energy. A review also found that using more daylight and changing lighting layouts can lower electricity bills.

-

Put taller items in the back and shorter ones in front.

-

Leave spaces between products for better airflow and lighting.

-

Rotate stock so older items stay in front and sell first.

Our display cabinets have shelves you can move and smart lighting layouts. These features help staff organize products for freshness and a nice look. Customers see a clean, bright display that makes them want to buy.

Energy Efficiency in Commercial Refrigeration

Saving energy is very important in commercial refrigeration today. The U.S. Department of Energy says ENERGY STAR certified refrigerators use up to 40% less energy than regular ones (source). Using less energy saves money and helps the environment. Operators who pick stainless steel cabinets with energy-saving features get better performance and save money over time.

Door Seals & Insulation

Door seals and insulation help keep cold air inside the cabinet. If seals are old or broken, cold air leaks out. This makes the compressor work harder and uses more energy. The Food and Drug Administration says to check door gaskets every month (FDA Food Code). Staff should clean the seals and replace them if they are cracked or not flexible. Good insulation, like polyurethane foam, keeps the temperature steady. It also stops water from forming and keeps food safe.

Tip: Staff should close doors fast and never leave them open. This easy habit saves energy and keeps food safe.

Night Blinds & Energy Modes

Night blinds and energy-saving modes help save energy when the store is closed. Night blinds are covers that staff pull down over open display cases at night. The Carbon Trust says night blinds can cut energy use by up to 33% (source). Many new commercial refrigeration units have energy modes. These settings lower lights and slow the compressor when the store is closed. Operators can set these modes to match store hours.

|

Feature |

Energy Savings |

Benefit |

|---|---|---|

|

Night Blinds |

Up to 33% |

Lower bills, less food spoilage |

|

Energy-Saving Modes |

10-20% |

Longer equipment life |

Our website’s display cabinets have strong insulation, tight door seals, and built-in energy-saving features. These cabinets keep food, ice cream, and desserts fresh and help lower costs.

Cleaning & Maintenance

Routine Tasks

Cleaning and taking care of commercial refrigeration display cabinets is important. The FDA says to clean surfaces and equipment often. This stops bacteria and mold from growing. Staff should have a cleaning schedule. This keeps food, ice cream, and desserts safe and fresh.

Key routine tasks include:

-

Wipe shelves and doors every day with a safe cleaner.

-

Clean up spills right away to stop sticky messes.

-

Clean condenser coils once a month for strong cooling.

-

Check and clean door gaskets to stop air leaks.

-

Empty and clean drip trays to stop water from building up.

Tip: Staff should use a checklist for cleaning jobs. This helps make sure nothing is missed and keeps cabinets working well.

A clean cabinet looks nice and works better. Our website’s display cabinets have easy-to-clean surfaces and shelves you can remove. These features help staff clean faster and keep displays looking neat.

When to Call a Pro

Some problems need a trained technician to fix them. Staff should look for warning signs that mean expert help is needed. The EPA says to call a pro for refrigerant leaks or electrical problems.

Call a pro if you notice:

-

The cabinet does not stay cold after cleaning.

-

Ice builds up on coils or inside the unit.

-

You hear strange noises or smell burning.

-

Water leaks that do not stop after cleaning.

|

Problem |

What to Do |

Who Should Fix It |

|---|---|---|

|

Temperature not stable |

Check settings, clean |

Technician if persists |

|

Ice buildup |

Defrost, clean coils |

Technician if repeats |

|

Electrical issues |

Unplug, report |

Technician |

Note: Our website’s display cabinets use advanced cooling systems. These systems help stop breakdowns and keep food, ice cream, and desserts fresh longer.

Cleaning often and knowing when to call a pro helps avoid big repairs. This keeps display cabinets working well and products looking good.

Smart Upgrades

Remote Monitoring

Today’s commercial refrigeration systems use remote monitoring. This helps them work better and last longer. Operators can see temperature, energy use, and refrigerant levels right away. They use IoT sensors for this. Staff can find problems early and stop big breakdowns. Many systems use AI and machine learning. These tools spot strange patterns before things break. These upgrades make repairs cheaper and help equipment last longer.

-

Staff get alerts if the temperature changes or there are leaks.

-

Automatic reports save time and help follow rules like the AIM Act.

-

Managers can use cloud dashboards and mobile apps from anywhere.

-

One system can control many locations for better efficiency.

-

These systems connect with building controls for easy setup.

-

Smart alarms and work orders cut down on false alerts and fix problems faster.

More businesses want remote monitoring now. The market is growing fast. Real-time alerts and cloud access are very helpful. This new way of working means fewer breakdowns and better energy use. Operators can fix problems quickly and keep food safe. This also lowers legal risks. Our website’s display cabinets use advanced monitoring. This keeps food, ice cream, and desserts fresh and looking good.

Automated Defrost

Automated defrost systems save energy and protect food quality. These systems remove ice by themselves. No one has to do it by hand. They keep the temperature steady during defrost cycles. Research shows automated defrost lowers freezer temperature rise by 4.74°C. It also saves 1.91% in energy use. Operators do not need extra hardware to get these savings.

|

Metric |

Value |

Description |

|---|---|---|

|

Freezer temperature rise reduction |

4.74 °C |

Decrease in temperature rise during defrost cycles |

|

Energy saving |

1.91 % |

Percentage of energy saved by automated defrost |

|

Hardware modification |

None |

Energy savings achieved without extra hardware |

Automated defrost puts less stress on compressors. It keeps products at the right temperature. This means less food goes bad and repairs cost less. Our website’s display cabinets have smart defrost technology. This keeps food, ice cream, and desserts fresh and looking great.

Operators who make their display cabinets better get real rewards:

-

Getting new units can use 30% less energy. This can save up to $720 each year (source).

-

Energy-saving models make bills lower and help the planet.

-

Smart monitoring and automatic defrost make cabinets work better and stop food from spoiling.

-

Money rewards can help pay for upgrades.

Doing regular checks, keeping the right temperature, having good airflow, and using bright lights keep food fresh and displays nice. Operators should check their ways often and try new technology to keep doing well.

FAQ

What temperature should commercial display cabinets maintain for food safety?

Most food safety rules say to keep cold foods at 41°F (5°C) or lower. This stops bacteria from growing. Good temperature control keeps food safe. FDA Food Code

Our oucboll brand's refrigerated display case use special cooling to keep food safe and fresh.

How often should staff clean commercial refrigeration display cabinets?

Staff need to clean shelves and surfaces every day. They should also clean coils and gaskets once a month. Cleaning often stops mold and keeps displays looking nice. CDC Cleaning Guidance

Removable shelves in our cabinets help staff clean quickly and easily.

Why is LED lighting recommended for display cabinets?

LED lighting uses less energy and lasts much longer than old bulbs. It also makes food, ice cream, and desserts look better. ENERGY STAR Lighting Facts

-

LED lights in our cabinets make products stand out and save energy.

What is the benefit of remote monitoring in commercial refrigeration?

Remote monitoring systems watch temperature and performance all the time. Operators get alerts if something is wrong. This helps stop food from spoiling and keeps food safe. ASHRAE Refrigeration Handbook

Our oucboll brand's refrigerated display cases have smart monitoring to help you worry less.

How do night blinds help save energy in display cabinets?

Night blinds cover open cases when the store is closed. They keep cold air inside and can lower energy use by up to 33%. Carbon Trust Refrigeration Guide

|

Feature |

Energy Savings |

Benefit |

|---|---|---|

|

Night Blinds |

Up to 33% |

Lower energy bills |

Our cabinets have energy-saving features for better operation.

English

English русский

русский Español

Español عربى

عربى